Applications of Tension and Compression: Civil, Mechanical, and Aerospace Engineering

Tension and compression are two forces that are immensely obvious in defining our world and are paramount in structures. They are forces that come into play every time an object is subjected to force in any way or form. Tension is the force that tends to elongate the object whereas compression is the force that tends to shorten the object.

Tension, Characteristics and Examples

Definition:

Force that acts in a direction to make an object longer is referred to as tension. It works in a direction opposite to the applied force and hence tends to pull the particles of the object apart. There is a falling into confusion here between applied force and tension, which is the force in the material that resists the force that is being applied to it.

Characteristics:

- Internal Force:

Tension is always an internal force within the object being stressed. It is the strength with which particles in the body of matter act upon each other in order not to be separated.

- Uniform vs. Non-Uniform:

Tension can be uniform if the force is applied in a uniform manner across the bar stretching it uniformly. It can also be non uniform if the force that is being applied acts randomly and some part of the object end up being stretched more than the other.

- Static vs. Dynamic:

Tension can either be static or dynamic meaning constant or changing over time respectively. For example, tension in a rope carrying a load is static. Whereas, tension on a string of a guitar is dynamic tension.

Examples:

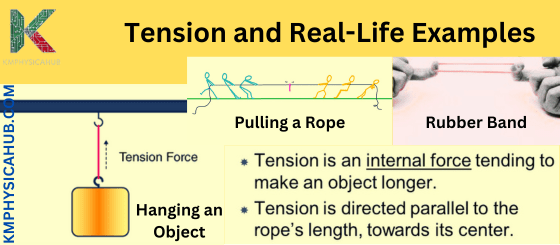

- Pulling on a Rope:

When a force is applied in an attempt to pull a weight using a rope, the force results into tension in the rope. The rope therefore does not allow itself to be elongated and thus help in pulling the weight.

- Stretching a Rubber Band:

Let’s study the example of a rubber band. Tension is created within its material when it is stretched. It can easily return to its original shape when stress is removed. Because the band is capable of storing energy when it is stretched. That energy is then used to restore its shape.

- Hanging a Picture:

When you have a picture hanging on the wall, the string or wire supporting the picture is in a state of tension. The tension of the string or wire should be sufficient for holding the picture and preventing it from falling off.

Molecular Level:

At the molecular level, tension is the process of elongating the strands that bind the atoms in the object.

Bond Stretching: The force applied to the object help to pull the molecules that compose the object apart from each other. The connections between these molecules are rigid against this stretching and this results in some sort of tension.

Resistance to Deformation: Such resistance to extension is what offers the body the ability to assume a specific shape or form and not deform. The higher the intermolecular forces in an object, the greater force the object can handle before breaking.

Compression, Characteristics and Examples

Definition:

Compression is a pushing force that squeezes or shortens an object. It acts in a direction opposite to the force applied, pushing the object’s particles closer together. Like tension, compression is an internal force within the object, resisting the applied force.

Characteristics:

- Internal Force:

Compression is always a force acting inside the object being compressed. It is the force that the molecules within the object apply in relation to each other to counteract any attempt to compress them.

- Uniform vs. Non-Uniform:

Uniformity can be obtained if the force exerted on the object is applied in equal amounts in all areas of the object, thereby compressing it equally. Non uniform compression is also possible if the force that compresses the material is applied non-uniformly across the body of the material so that some sections are compressed at different rates than other sections.

- Static vs. Dynamic:

Static or constant compression is the type that does not change over time while dynamic compression is the type that modifies over time. For instance, the compression in a spring which supports a weight is static, while the compression of a shock absorber interacting with bumps on the surface is dynamic.

Examples:

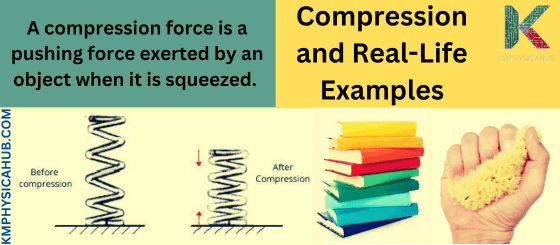

- Pushing on a Spring:

When you are compressing something such as a spring, what you are actually doing is adding force in the spring. The spring resists being compressed, storing energy and pushing back when released.

- Stacking Books:

Let us consider the act of arranging some books by laying them one over the other. In this case the bottom book gets compressed under pressure from the ones placed on top of it.

- Pressing on a Sponge:

Compression is formed within the material of the sponge when you apply pressure on it. The sponge does not easily deform under pressure, it stores the force and then pops back to its original shape.

Molecular Level:

On the molecular level, the compression applies force to squeeze the atoms of an object and decrease the space between the atoms.

Bond Compression: Whenever a force is applied on an object, the molecules of the object are brought closer to each other. These molecules always try to resist the fore causing compression.

Resistance to Deformation: The ability to resist is the reason that the object does not change shape and get deformed. The extents to which an object is capable of being compressed without being flattened directly correlates with the forces that govern the bonding of molecules.

Relation between Tension and Compression

Equilibrium:

Stability in many cases arises from the interaction between tension and compression forces. They are often in a state of equilibrium, whereby the forces act in opposition to each other.

Balanced Forces:

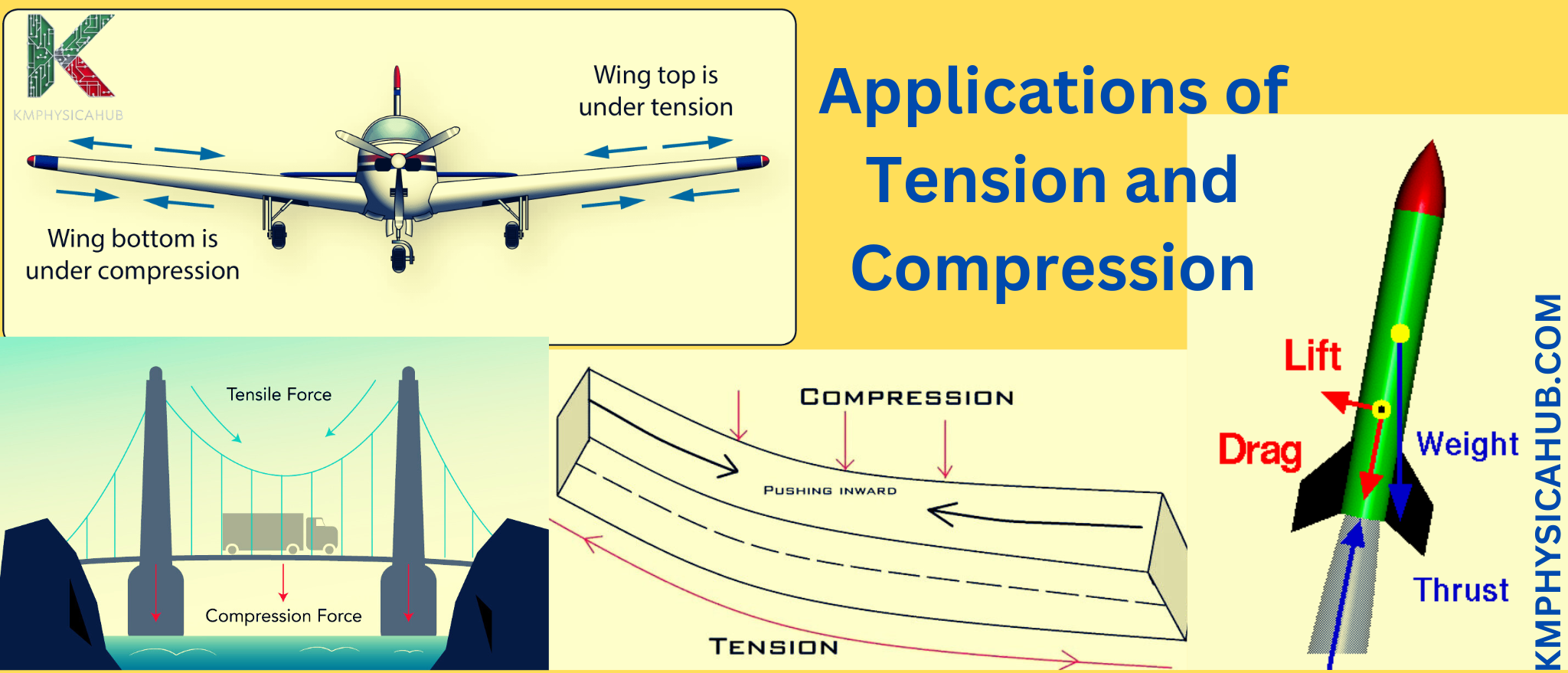

In many structures, there is a balance of tension and compression forces. It means that they are equal in magnitude but are acting in opposite direction to ensure stability. For instance, in suspension bridges, tension acts on the cables while compression acts on the towers and the roadway of the bridge. The balance between them enhances stability of the bridge to carry traffic loads and also other loads such as wind loads.

Stress and Strain:

When tension or compression force acts on an object, stress and strain become considerable factors.

Stress:

The force per unit area within a material or an object that acts against deformation is referred to as stress. It is expressed as the force acting on the cross-section of the material.

Strain:

The deformation of a material under stress is called strain. This is a measure of the degree to which a material changes its dimensions.

Relationship:

Stress and strain are in direction proportion to each other. The higher the stress, the higher the strain. However, there are cases where stress is not directly proportional to strain. Materials have a unique curve known as stress-strain curve, which defines their behavior under the application of loads.

Failure Points:

All materials have their maximum capacities for stress and strain that they are capable of handling without breaking. Exceeding these limits can result in failure of structures.

Yield Strength:

The point at which an object or a material deformed permanently is called yield strength. Beyond this point, the object or material will not restore its original shape.

Ultimate Strength:

It is defined as the maximum amount of stress that an object can bear without cracking. When this point is attained, the material will split apart.

Safety Factors:

In engineering, structures are designed with safety margins for any uncertainties existing in material properties, loads, and service conditions. Safety factors make structures capable of withstanding loads far much higher than their normally expected loads.

Applications in Civil Engineering

The concepts of tension and compression form the basis of engineering practice and provide the principles for creating various structures, mechanisms, and technologies.

-

Bridges and Structures:

Tension and compression form the basic principles of the bridge construction. Examples of structures that show this principle are suspension bridges whose cables rely on tension to support the weight of the roadway. The cables are suspended from large compression towers that feel the bulk of the bridge weight and the tension from the cables.

Cables: Suspension bridge cables are expected to be able to bear very high tension as they extend horizontally to support the loads from the bridge structure. This tension is countered by the compression in the towers.

Towers: The towers of the suspension bridge have to support massive compression where weight is being pushed down towards the ground counteracting the tension force exerted by the cables.

-

Foundations and Soil Mechanics:

It is essential to comprehend the conflict between tension and compression in soil in order to specify a stable base of any construction.

Soil Compression: The weight of the building places a pressure on the ground and this result in compacting of the particles. This compression may also negatively impact the stability of the foundation.

Soil Tension: In some instances, stress might build up on the soil as a result of the water movement or a change in temperature. This condition can cause soil expansion and may affect the structure’s foundation.

Applications in Mechanical Engineering

-

Machines and Mechanisms:

Tension and compression are vital in production of gears, levers and other pieces of mechanical structures.

Gears: Gears are used to transmit power and alter the speed or direction in which the rotation occurs. Both tension and compression forces are observed on the teeth of the gears upon engaging in interaction.

Levers: Levers are simple machines that strengthen force. The force that is being applied to the lever generates tension in the lever arm and this results in compressive forces at the pivot point.

-

Stress Analysis and Fatigue:

Stress analysis is employed by engineers in order to identify how the forces of tension or compression influence a material. They also take into account fatigue which is the progressive loss in the strength of a material that occurs as a result of applying load and then removing it in a cyclic manner.

Stress Concentration: Stress tends to focus on specific areas like the corners or at the holes which means that these regions experience significantly more stress and are likely to fail.

Fatigue Failure: When a material is subjected to tension and compression for many times then the body develops cracks and ultimately fails.

Applications in Aerospace Engineering

-

Aircraft Design:

Stress and strain are essential in the quest for achieving lightweight and efficient structures for the aircraft. It is also important to maintain their motion properly.

Wings: The wings of the aircraft are constructed to provide lift through the help of the flow of air. The top surface of the wing has reduced pressure leading to tension while the bottom surface has increased pressure hence compression. This difference in pressure creates lift.

Fuselage: The body of an aircraft is made to bear the loads of the pressure in the air, winds loads, and the impacts during landing. Tension and compression elements are equally used in the construction of the fuselage to achieve the best strength and minimal weight.

-

Rocketry and Spacecraft:

Tension and compression are essential to lift and control rockets and space crafts through various designs.

Rocket Engines: Rocket engines work on the principle of the exhaust of hot gasses at a high velocity to achieve the force required to propel the rocket. The combustion chamber of the engine has high pressure that provide compression forces and thus pushes the rocket forward.

Spacecraft Structures: Satellites are engineered to handle the conditions of space such as the vacuum, temperatures, and radiation. They are usually made of light weight materials that have ability to bear tension as well as compression.

Conclusion:

Tension and compression forces are basic forces that exist in the world of physics. They play a significant role in infrastructure designs, whether it is a bridge, a building, a vehicle or a machine. These forces are necessary for the current society and help us construct tall structures, invent more efficient technologies, and study the world around us.

Tension and compression studies are still ongoing and researchers are working on new materials and performing experiments and calculations towards a more efficient structural and engineering design.

FAQs:

Q1. What is tension?

A: Tension is force which has the ability to pull an object in a particular direction by exerting force that stretches an object. Imagine the elastic pulled to the maximum extent.

Q2. What is compression?

A: A force that shortens an object is referred to as compression(pushing force). Think of a sponge being pressed.

Q3. How are tension and compression related?

A: They are opposite forces that often work together in structures. Tension pulls, while compression pushes, creating balance.

Q4. Write three examples of tension in real life?

A:

- Suspension bridge cables

- Tightrope

- Guitar string

Q5. Write three examples of compression in real life?

A:

- Building pillars

- Hydraulic systems

- Springs

Q6. Is tension always a positive force?

A: No, excessive tension can lead to breakage or failure. It’s crucial to design structures that can handle the forces effectively.

Q7. Is compression always a negative force?

A: No, compression is necessary for many applications, such as in hydraulic systems and springs. However, too much compression can also cause damage.